MarineShift360 has released the first findings from its Impact Accelerator programme, outlining how lifecycle analysis has informed decisions at the Royal National Lifeboat Institution (RNLI) and BAR Technologies.

The ten-month programme, supported by 11th Hour Racing and led by consultancy Marine Futures, guides marine organisations in applying lifecycle analysis to identify environmental hotspots, inform design and supply-chain decisions and develop practical sustainability measures.

Initial results indicate that data-led assessment can support decarbonisation efforts, reduce costs and reinforce resilience across the marine sector.

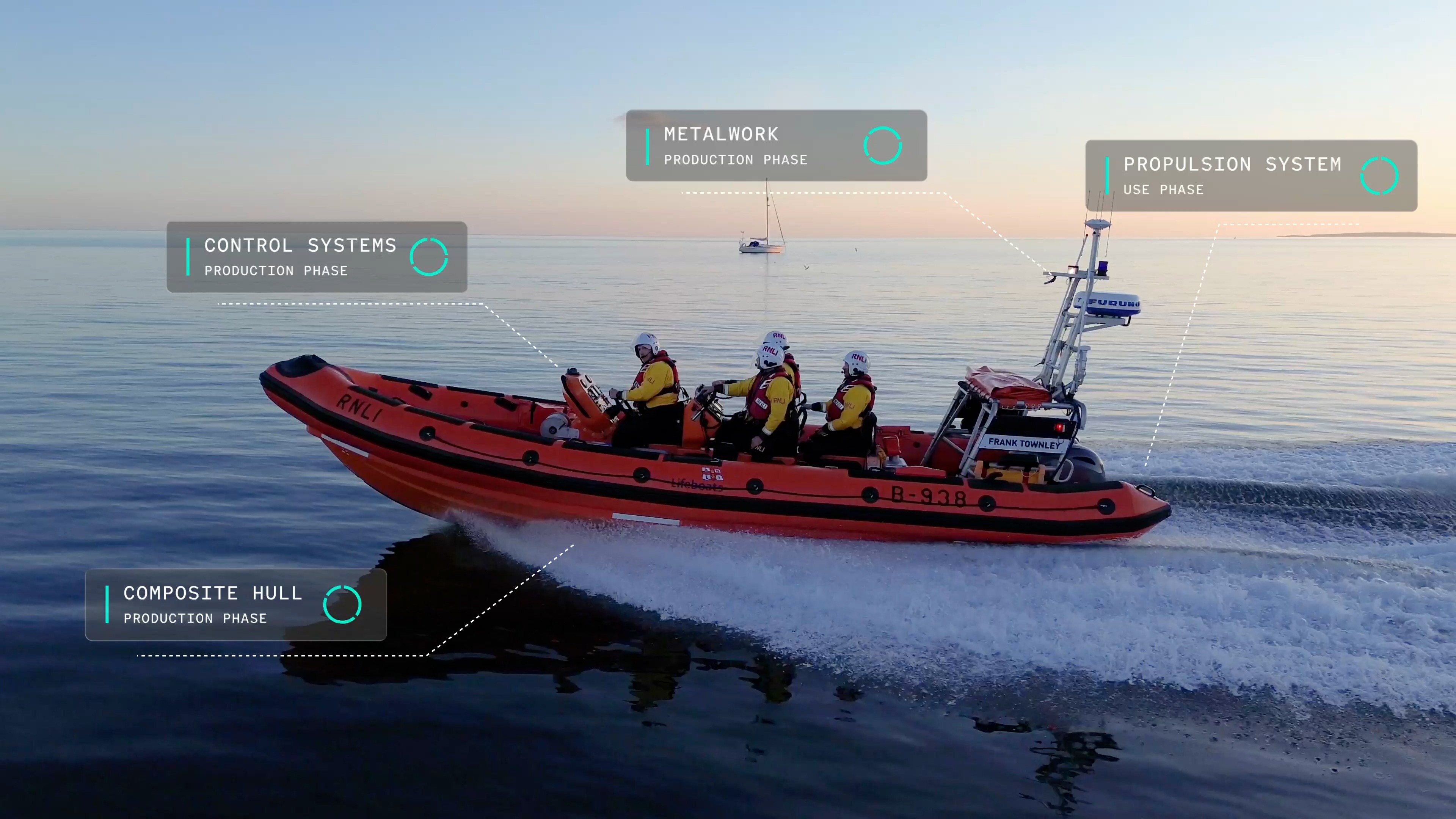

Rescue charity RNLI says it took part to gain a clearer understanding of the environmental impact of its fleet and to support operational, design and investment planning. It used the Atlantic 85 as the pilot vessel to create an approach that could be applied at scale.

The analysis showed that over an 18-year lifespan, around 82 per cent of the vessel’s lifecycle impact is linked to the use phase, with the remaining 18 per cent associated with production.

Emissions varied between lifeboat stations, influenced mainly by duty cycle (rather than construction). The study also provided more detailed data on production hotspots. Mouldings represented 34 per cent of embodied emissions, energy use 23 per cent and drivetrain components 18 per cent. The RNLI is now drawing on these findings.

Efficiency opportunities at under 7kn are contributing to the Mark 4 Atlantic 85 development programme, according to the charity, while materials and processes are being reviewed to reduce carbon fibre use and increase recycled content. An energy audit is also underway.

The method developed through the study is being prepared for use with larger classes, such as the Tamar, where fuel use and associated carbon and cost impacts are higher.

“Without this study, it’s difficult to say where to put our efforts. With it, we can prioritise and reduce our impact,” says Todd Gillingham, ES PMO & resource lead at the RNLI.

“Sustainability can feel abstract, but when you see the efficiency gains and the fuel savings, the value becomes clear. This work helps ensure we’re using donor money effectively, which is better for the environment, better for our crews and better for the communities we serve.”

BAR Technologies, a team of fluid dynamists, naval architects and composite specialist control engineers, is looking to push technological advances, specifically in the field of wings for cargo ships. The firm says it joined the programme to assess the carbon payback of its WindWings, rigid wing sail systems intended to reduce fuel use and emissions on commercial vessels.

The analysis provided new lifecycle data for commercial shipping. It found that emissions saved during operation quickly exceed those generated during the manufacture of a WindWing. Under baseline assumptions, the carbon payback period is around six months and remains under a year in more conservative cases.

“Seeing the payback come out in months has validated our design approach,” says Will Hopes, simulation and performance engineer at BAR Technologies. “It has changed how we describe and develop our products and made lifecycle impact a core part of every design review, not a separate consideration.”

The study also identified further reduction opportunities. Metalwork accounted for 33 per cent of embodied emissions, prompting updates to procurement specifications to include higher recycled content and the use of Electric Arc Furnace produced steel. Tooling impacts are being reduced through increased utilisation and greater use of recycled inputs.

Lifecycle analysis is now shaping engineering and commercial discussions within BAR Technologies and informing engagement with shipowners, regulators and investors.

“These results show what is possible when organisations commit to fully understanding their impact,” says Ollie Taylor, appointed director of Marine Futures in 2022. “Lifecycle analysis gives leaders the data to make better decisions and the confidence to scale those decisions across fleets, supply chains and product lines. As a first year, these results are incredibly encouraging and show what the Impact Accelerator was created to do, which is to catalyse change across our industry.”

Jeremy Pochman, co-founder and CEO of 11th Hour Racing, adds: “Decarbonisation in the marine sector can feel overwhelming, but it doesn’t need to be. MarineShift360 brings clarity — delivering the data, expertise, and practical pathways that help organisations turn big sustainability goals into meaningful near-term progress. We’re committed to backing innovators who aren’t waiting for every variable to line up — they’re building the future of a low-impact marine industry right now.”

Applications for the 2026 Impact Accelerator are now open.

The post MarineShift360 releases first findings from vessel lifecycle analysis appeared first on Marine Industry News.

Leave a Reply